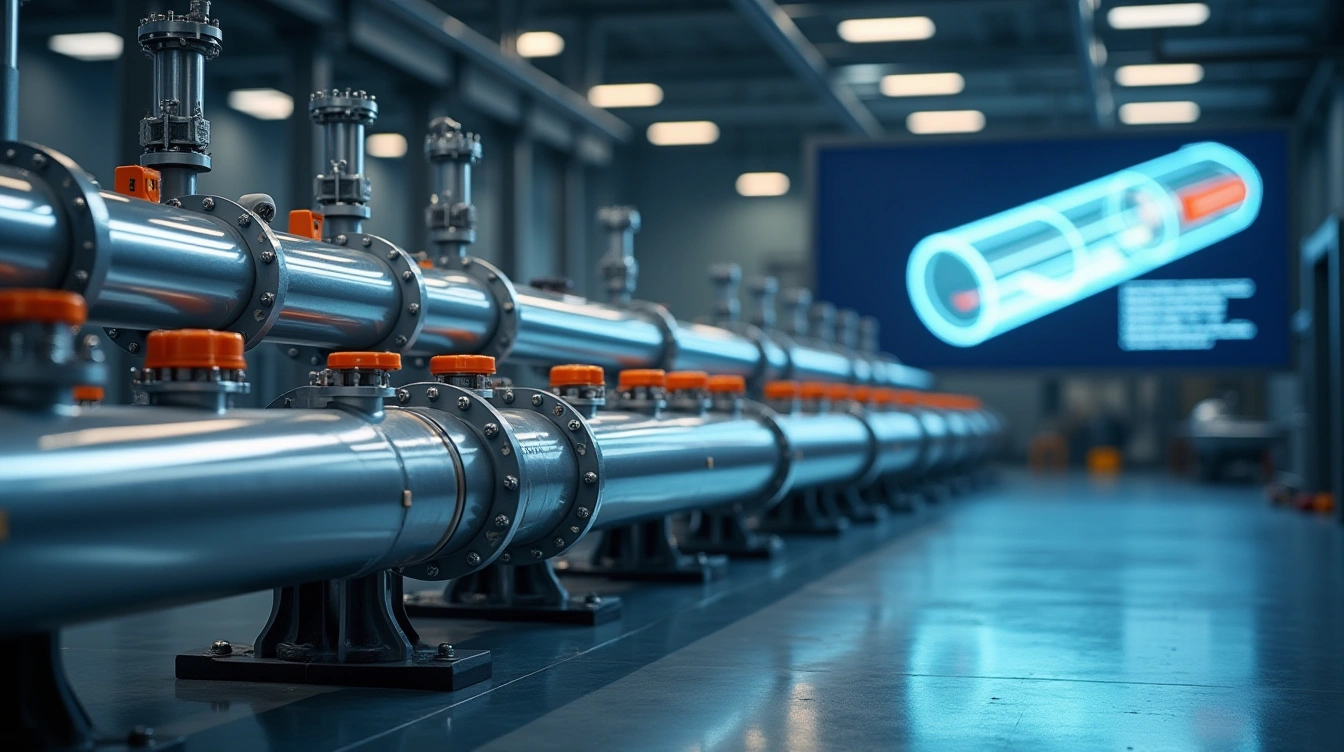

The rapid evolution within the energy sector demands new standards for performance, efficiency, and safety at every level. Among the most critical components, steel tubes hold a pivotal role—particularly in oil and gas, renewable projects, and heavy industrial applications. Today’s smart tubular solutions sit at the crossroads of advanced technology and digital innovation, delivering more than just robust infrastructure. They provide real-time insights, improved sustainability, and unmatched value to operators worldwide.

What defines smart tubular solutions?

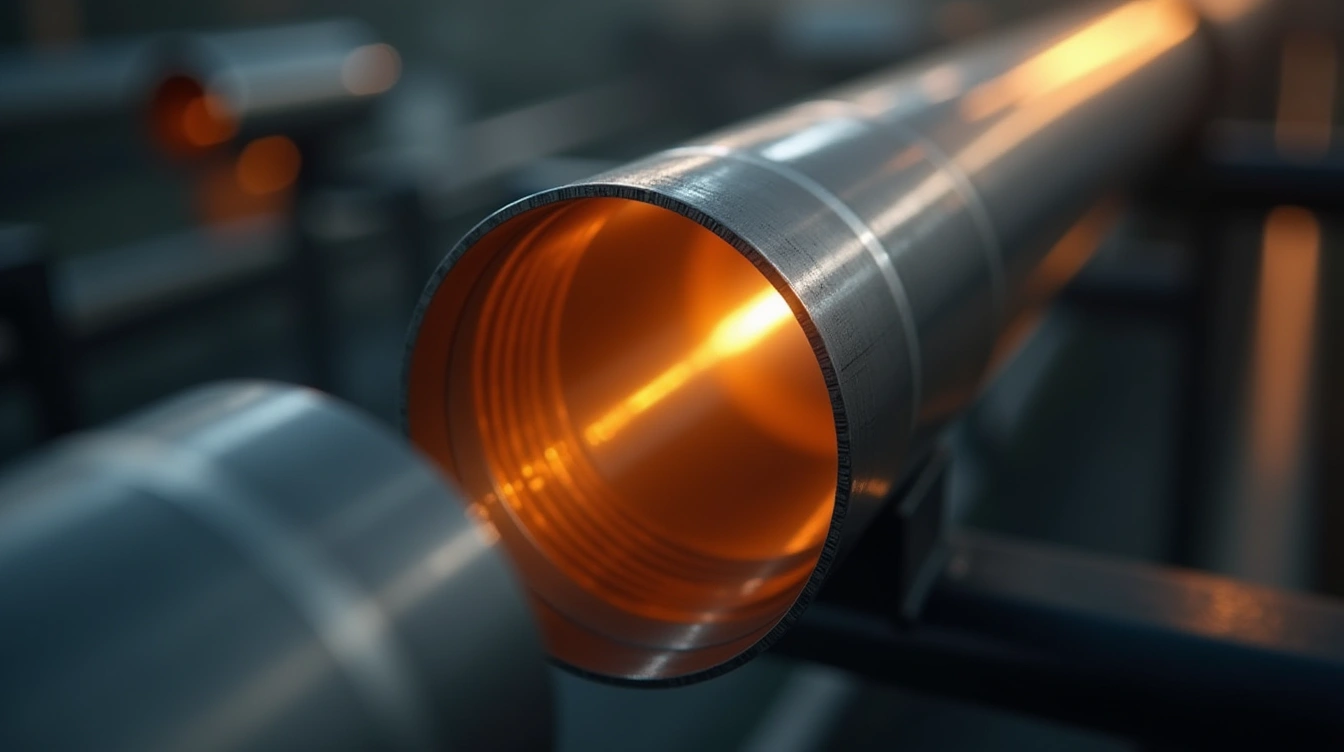

Smart tubular solutions go beyond traditional steel tubes by embedding sensors, enabling data communication, and integrating predictive analytics directly into their structure. This combination unlocks greater operational visibility and allows continuous monitoring, even in harsh environments like those encountered in oil and gas exploration.

In parallel : What Strategies Can UK Businesses Implement to Enhance Growth and Innovation?

The outcome is a network that can self-diagnose, alerting engineers to issues before they escalate and supporting automatic adjustments for optimal conditions. Whether used for drilling wells or managing extensive storage facilities, this approach reduces downtime and extends the operational lifespan of vital assets.

The impact on the energy sector

With growing emphasis on cleaner practices and higher efficiency, tubular solutions built on advanced technology platforms are meeting these evolving challenges head-on, especially in demanding upstream and downstream operations. For further insight, you can explore information with the vallourec.com website.

This might interest you : What Emerging Business Trends Are Transforming the UK Market?

Operators choosing these systems experience increased reliability, better asset management, and strengthened sustainability. The shift toward digitized tubular assets is reshaping how companies plan, monitor, and maintain installations across the lifecycle.

Changing oil and gas operations

Within oil and gas fields, maintaining tubular integrity is essential for both productivity and safety. Smart systems make real-time health assessments standard practice. Pipelines equipped with diagnostics can notify teams about abnormal thermal or pressure variations, prompting swift interventions that prevent accidents and resource loss.

This strategy not only minimizes non-productive time but also prolongs asset service life. Engineers operate with greater confidence when using tubular solutions engineered for high-pressure, corrosive, or remote offshore environments.

Supporting renewable energy deployment

Steel tubular components form the backbone of wind turbine towers, geothermal wells, and solar panel supports. When enhanced with smart capabilities, these structures enable proactive condition monitoring, adjust to environmental stressors, and reduce manual inspection requirements.

As the global energy mix diversifies, deploying intelligent steel tubes ensures infrastructure remains resilient under growing demand. These advances also reinforce lifecycle management, a cornerstone for achieving long-term sustainability objectives.

Main drivers behind adoption

Breakthroughs in digital innovation and materials science have paved the way for next-generation tubular solutions. Decision-makers now focus on lifecycle benefits and resilience, moving beyond initial cost considerations.

Key factors accelerating adoption include stricter regulations, competitive market pressures, and rising expectations around safety and environmental stewardship. Companies leveraging these smarter solutions can demonstrate compliance while reducing unplanned outages and financial risks.

- 🚦 Enhanced performance in varied operating conditions

- 🛡️ Improved safety via automated alerts and intervention tools

- 🌱 Greater sustainability through longer asset life and lower emissions

- 💻 Efficiency gains from digital integration and predictive maintenance

Industrial applications beyond energy

While championed initially in energy sectors, smart tubular solutions bring measurable benefits to a range of industries. Steel tubes featuring embedded sensing and connectivity empower plant managers, civil engineers, and transportation specialists alike.

For example, large manufacturing plants rely on advanced piping networks for steam and fluids. With real-time monitoring, leaks are detected early, scaling build-up is predicted, and cleaning schedules are optimized—leading to smaller maintenance budgets and reduced waste generation.

Innovations in construction projects

Modern skyscrapers and bridges often use structured tubing for stability and load-bearing needs. By incorporating sensors, these elements become active participants in building health. If unusual strain or temperature changes occur, supervisors receive instant notifications to act promptly.

This advancement results in safer public spaces, data-driven renovations, and insurance savings for project stakeholders.

Boosting performance in transport and water infrastructure

Water distribution systems and rail networks benefit greatly from adopting advanced tubular components. Issues such as fatigue, vibration, or leakage, if left undetected, can threaten reliability. Digital monitoring ensures rapid detection and enables timely repairs, keeping essential services uninterrupted.

The resulting reduction in losses and fewer service interruptions highlight the practical advantages of embracing modernized tube solutions in daily urban life.

The move towards sustainability and safe practice

Environmental responsibility shapes much of today’s engineering progress. Integrating smart functionality into tubular systems strengthens green initiatives: energy consumption drops, hazardous release risks decrease, and resources are conserved throughout extended equipment cycles.

Simultaneously, advanced designs raise installation integrity—a key factor in safeguarding people and property. Automated inspections reduce human error, while comprehensive reporting keeps all parties informed and accountable.

| 🌍 Sustainability feature | ⚡ Impact on operations |

|---|---|

| Real-time leak detection | Fast containment limits pollution risk |

| Predictive maintenance | Reduces unnecessary replacements and waste |

| Corrosion monitoring | Prevents structural failures and material loss |

Frequently asked questions about smart tubular solutions

How do smart tubular solutions enhance safety?

These solutions utilize embedded sensors to track critical parameters such as pressure, temperature, and vibration. When anomalies arise, automated alerts trigger quick corrective action, reducing failure risks and improving emergency response times.

- ⏰ Early problem detection

- 🆘 Faster emergency response

- 🔒 Continuous surveillance without exposure to hazardous conditions

Which industrial applications benefit most from advanced tubular technologies?

Industries requiring high reliability and precise process controls achieve significant improvements. Energy, chemicals, manufacturing, and transport sectors all depend on uninterrupted operation, where minimum disruption is essential. Smart tubular solutions are particularly prevalent in:

- 🛢️ Oil and gas extraction

- 🏭 Refining and chemical processing

- 🌬️ Renewable power (wind, geothermal)

- 🚅 Railways and water supply

Can smart tubular solutions improve sustainability efforts?

Yes, intelligent steel tubes extend service life, reduce the need for frequent, resource-intensive repairs, and help avoid accidental releases that could harm the environment. Data-driven maintenance optimizes performance and curtails waste, supporting broader organizational sustainability goals.

- 🌱 Fewer emissions due to less frequent breakdowns

- 🔄 Optimized replacement cycles

- ♻️ Streamlined recycling of assets at end-of-life

| 📈 Benefit | 🌿 Environmental impact |

|---|---|

| Lower energy usage | Decreased carbon footprint |

| Leak prevention | Protects water and soil |

What technologies enable smart tubular solutions?

Integrated sensor arrays, wireless data transmission, artificial intelligence for pattern recognition, and cloud-based analytics all contribute to making these products intelligent. Collaboration between materials science and information technology companies continues to accelerate progress in this field.

- 📡 Remote monitoring interfaces

- 🤖 Automation algorithms for diagnostics

- 📊 Predictive analytics platforms

In summary, Vallourec’s smart tubular solutions are redefining what is possible in the energy and industrial worlds. As technology evolves and sustainability becomes ever more crucial, these innovations offer a blueprint for safer, more efficient, and environmentally responsible operations. Looking ahead, continued collaboration and investment in advanced tubular technologies will be key to meeting future industry challenges.